Database and Data Submission Systems

Languages

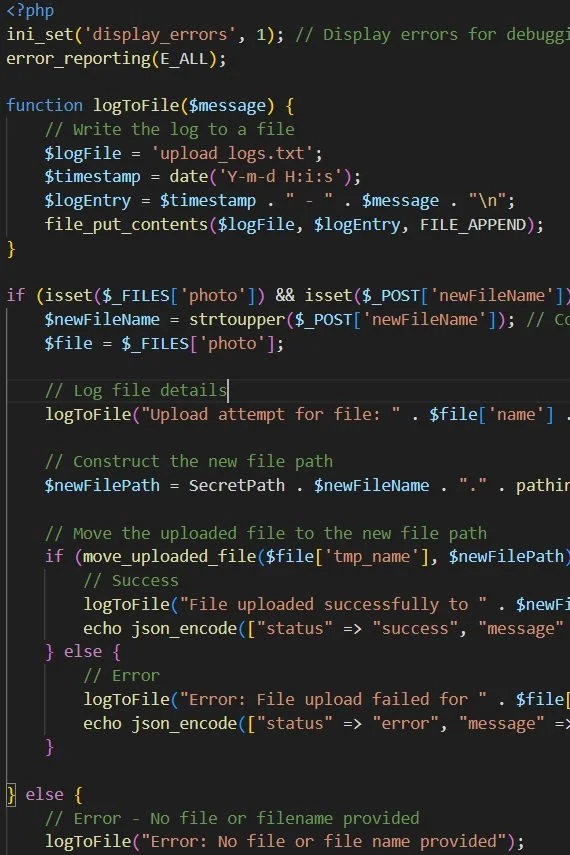

We can program in mulitple languages to best fit your needs. We offer development of custom Python scripts for automation and data processing, dynamic web applications for efficient data entry using intuitive HTML interfaces, and SQL databases for secure and scalable data storage.

We typically use modbus and PHP for data transfer between programs.

By integrating these technologies, we provide powerful tools for data interpretation, enabling our clients to extract meaningful insights, automate workflows, and make informed decisions based on real-time data analysis. Whether you need standalone tools or a fully integrated system, we deliver tailored solutions that work seamlessly together to meet your business needs.

Previous Projects

Automated Report Generation System: Python scripts collect and process raw data from various sources, storing the results in an SQL database. A web app built with HTML allows users to input parameters for reports, and the system automatically generates detailed reports and visualizations based on real-time data for improved decision-making.

Inventory Management System: A web-based data entry platform allows employees to log inventory changes, and Python scripts monitor stock levels, automatically generating purchase orders when supplies run low. SQL databases store all inventory data, ensuring historical records and trends can be analyzed for optimized inventory control.

IoT Data Monitoring System: A Python-powered back-end can collect data from IoT sensors, storing it in an SQL database for real-time monitoring. A web app provides users with a dashboard that visualizes the data, sending alerts when abnormal readings are detected, helping users take proactive action.

Quality Control System: Users enter inspection data through a web-based HTML interface, recording measurements, test results, or defect counts for products in real time. These values are stored in an SQL database for tracking and historical reference. Python scripts then analyze the entered data against predefined quality standards and thresholds, instantly identifying any deviations or issues. Based on this analysis, the system provides immediate feedback, offering corrective actions or adjustments that need to be made in the production process.

Schedule Now

Interested in working together? Please fill out this contact form or reach us immediately with a phone call!